Knowledge Base

Triaxial System

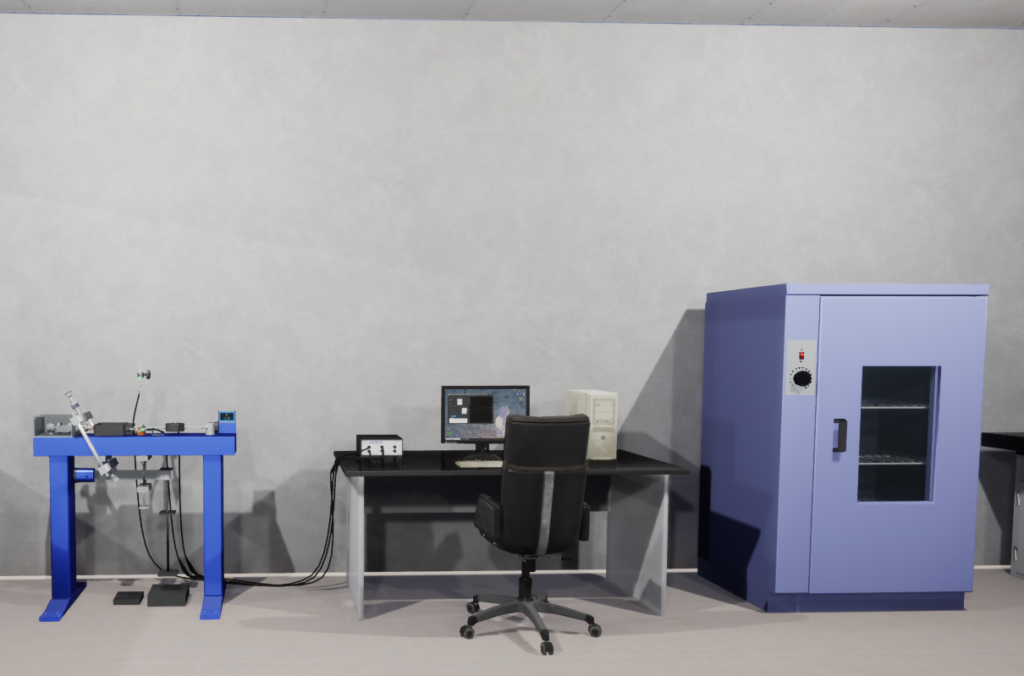

The triaxial test is a fundamental method in geotechnical engineering used to determine the mechanical properties of soils under different stress conditions. Equipment used for this test, commonly known as triaxial testing equipment, consists of several key components.

Firstly, there is the triaxial cell, which is a cylindrical chamber where the soil sample is placed. This cell is designed to confine the soil specimen radially while allowing for axial loading and drainage. The triaxial cell typically consists of a top cap, base pedestal, and a rubber membrane that encases the soil sample.

The equipment also includes a loading system capable of applying axial stress to the soil specimen. This loading system can be pneumatic, hydraulic, or mechanical, depending on the desired testing conditions. It allows for precise control over the axial stress applied to the soil sample.

Additionally, triaxial testing equipment features a means of applying confining pressure to the soil specimen. This is typically achieved using a confining pressure chamber surrounding the triaxial cell. The confining pressure chamber can be pressurized with water, oil, or gas to simulate different stress conditions experienced by soils in the field.

Instrumentation such as pressure transducers, displacement transducers, and pore water pressure measurement devices are integrated into the triaxial testing equipment to accurately monitor the stress and deformation behavior of the soil specimen during the test.

Triaxial testing equipment is essential in geotechnical laboratories for evaluating the strength and deformation characteristics of soils under different stress states. This information is critical for designing structures such as embankments, slopes, and earth-retaining structures to ensure their stability and safety

Direct Shear

The direct shear test is a fundamental method in geotechnical engineering used to determine the shear strength parameters of soils. Equipment used for this test, commonly known as direct shear equipment, consists of several components.

Typically, direct shear equipment includes a shear box assembly where the soil sample is placed. This assembly allows for horizontal displacement of one half of the sample relative to the other, simulating shear deformation. The shear box is equipped with porous stones or filters to allow for proper drainage during the test.

The equipment also includes a loading system that applies a normal load to the soil sample, simulating the vertical stress it experiences in the field. This load can be applied through weights or hydraulic systems.

Additionally, direct shear equipment features a means of applying horizontal displacement or shear force to the soil sample. This can be achieved through mechanical systems such as hand cranks or hydraulic actuators, allowing for precise control over the shear displacement.

Finally, instrumentation such as load cells and displacement transducers are integrated into the equipment to measure the applied load and displacement during the test accurately.

Direct shear equipment is crucial in geotechnical laboratories for assessing the shear strength properties of soils, which are essential for designing safe and stable structures such as foundations, embankments, and retaining walls.